Difference between revisions of "VT3000 - Wired Input Connection (IO Module)"

SupportAdmin (talk | contribs) |

SupportAdmin (talk | contribs) |

||

| Line 50: | Line 50: | ||

[[Category:VT3000 Core Software]] | [[Category:VT3000 Core Software]] | ||

[[Category:Device Hardware]] | [[Category:Device Hardware]] | ||

[[Category:Inputs]] | |||

[[Category:TIM]] | [[Category:TIM]] | ||

[[Category:PSM]] | [[Category:PSM]] | ||

Revision as of 17:07, 10 May 2021

Overview

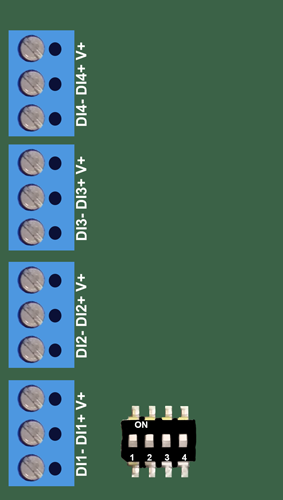

The instructions in this guide apply to the I/O Module for the PSM, TIM, and Wireless Switch Contact Module. Two types of input circuits can be used it this module, dry contact or DC signal. Each of the (4) contacts can be configured separately. The configuration is decided by the state of the associated switch (S1) and which of the 3 terminals the wiring is connected to. In either case, the yellow LEDs signify the state of the input. The red LEDs indicate that the module is powered.

Dry Contact

The dry contact configuration looks for a contact closure/open between DI#+ and V+. There should be no voltage connected to this input. The associated switch should be in the ON position. If you need to switch between normally-open/normally-closed operations, this can be accomplished with in the VT3000 software by using the Inverted setting.

DC signal

The DC signal configuration looks for a DC voltage input. This input is looking for a change in the voltage state from a high state of anything over 1.5 – 26 VDC to a low state of 0 - 0.9 VDC. The positive should be DI#+ and the negative end should be hooked up to DI#-. The associated switch should be in the OFF position. If the signal occurs on the rising (low to high) or falling (high to low) edge, this can setup in the VT3000 software by using the Inverted setting.

Production Performance Measurement Using Switch Contacts

- Downtime – Use this contact to signal when the equipment is in a down state (not producing). The customer decides what constitutes downtime. Depending on the equipment, the signal can come from a few different sources.

- PLC or Control Circuitry - this is the easiest method to pull a contact from. Many times this can come from a non-Auto Run state. It is possible to connect multiple relays in parallel to achieve the desired result. For example, the equipment could be considered down when there is a power loss, the E-stop has been activated, or there is no power to a certain motor.

- Count – Use this contact to signal when a part has been completed. Depending on the type of equipment, the contact can come from a variety of different sources - a sensor such as an electronic eye, a signal such as a machine cycle, or even an external button press from an operator.

- Equipment Fault – Use this contact to determine when equipment generates a fault. The contact would come from a PLC or other control circuitry equipment.

- Sensor Limit – Use this contact to determine when a sensor reaches a critical limit. This required a special type of sensor to trip a contact at a certain point. Common examples are the monitoring of temperature, pressure or some fluid level.

Step by Step Guides

Add a Virtual Count (TIM or PSM

Add a Count to a PC Input Module

Having Trouble?