VT3000 - Wired Input Connection (IO Module)

Jump to navigation

Jump to search

|

|

|

Overview

|

Requirements

|

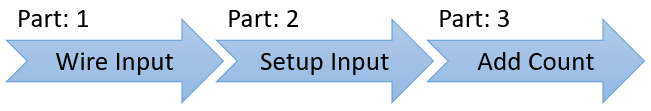

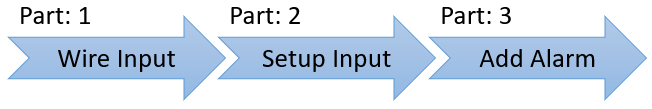

Completion Steps

| ||||||||

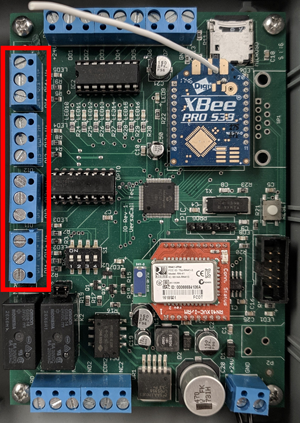

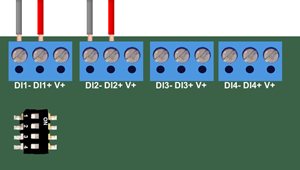

I/O Circuit Board

|

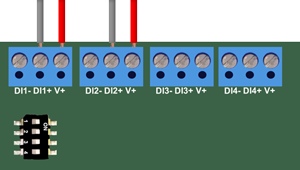

Dry Contact Connection

|

DC Signal Connection

|

Dry Contact

|

DC Signal

|

Downtime

|

Count

|

Equipment Fault

|

Sensor Limit

|

|

|

|

|